We tell you which heat exchanger is the right for you

7 reasons why rbi isyour best partner for tube bundle heat-exchangers.

Europs innovative manufacturer: we are rbi

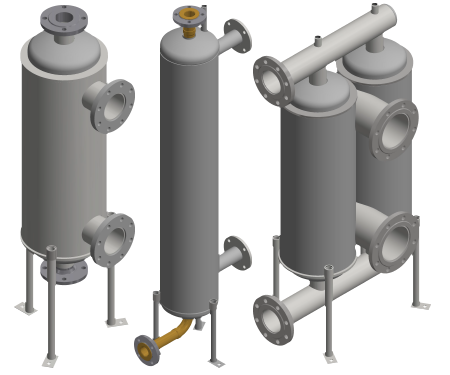

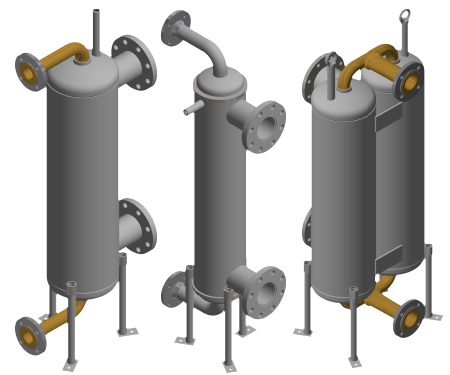

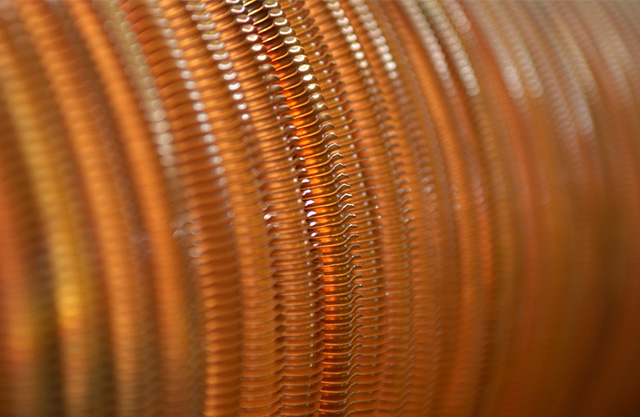

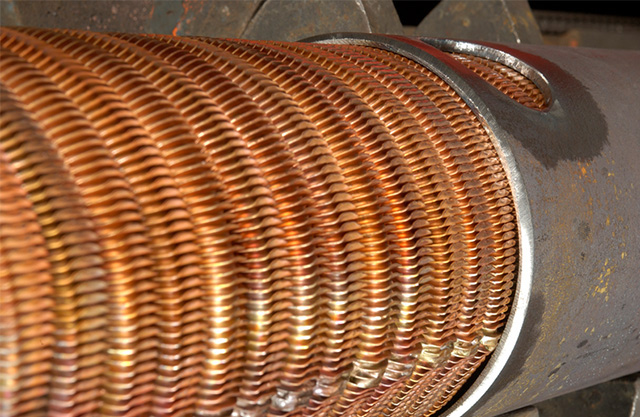

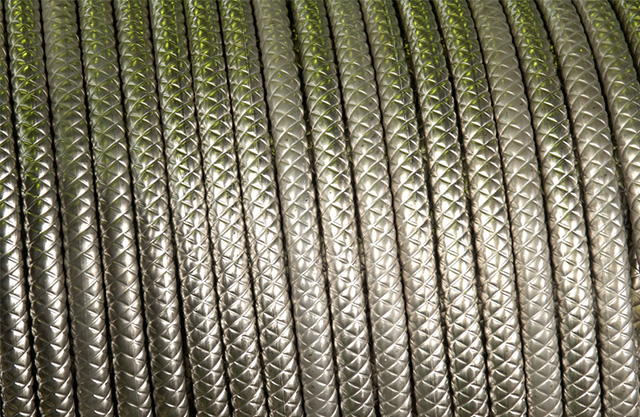

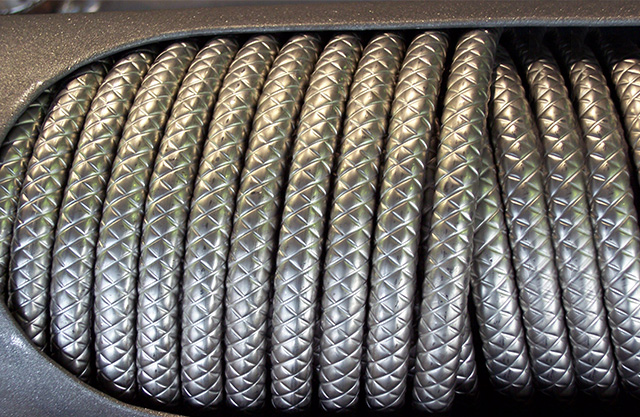

We are rbi – your heat exchanger manufacturer for wound tube bundle heat exchangers made of stainless steel and copper. For 30 years we have been you partner in the field of heat transfer in the realization of demanding, complex and international projects. Our princible applies is: does not work – does not exist: we work out individual solutions tailored to you and can also convince with our series products. We are constantly innovating with new ideas to meet the challenges of good and collaborative relationships with our customers to deliver the best and most competitive product. We have an international sales network and many cooperations with well-known companies. This is the basis for a trusting, partnership-based and long-term customer relationship.

Competent

Determined

Customer oriented

Innovative

Reliable

Product quality

Permanent optimization

Let`s get intouch with us!

Impressum

Angaben gemäß § 5 TMG

rbi GmbH

Im Rohrbach 18

57334 Bad Laasphe

Vertreten durch:

Gina Alisa Barth

Kontakt

Telefon: 02754 2208030

E-Mail: info@rbigmbh.de

Verbraucherstreitbeilegung/Universalschlichtungsstelle

Wir sind nicht bereit oder verpflichtet, an Streitbeilegungsverfahren vor einer Verbraucherschlichtungsstelle teilzunehmen.

Haftung für Inhalte

Als Diensteanbieter sind wir gemäß § 7 Abs.1 TMG für eigene Inhalte auf diesen Seiten nach den allgemeinen Gesetzen verantwortlich. Nach §§ 8 bis 10 TMG sind wir als Diensteanbieter jedoch nicht verpflichtet, übermittelte oder gespeicherte fremde Informationen zu überwachen oder nach Umständen zu forschen, die auf eine rechtswidrige Tätigkeit hinweisen.

Verpflichtungen zur Entfernung oder Sperrung der Nutzung von Informationen nach den allgemeinen Gesetzen bleiben hiervon unberührt. Eine diesbezügliche Haftung ist jedoch erst ab dem Zeitpunkt der Kenntnis einer konkreten Rechtsverletzung möglich. Bei Bekanntwerden von entsprechenden Rechtsverletzungen werden wir diese Inhalte umgehend entfernen.

Haftung für Links

Unser Angebot enthält Links zu externen Websites Dritter, auf deren Inhalte wir keinen Einfluss haben. Deshalb können wir für diese fremden Inhalte auch keine Gewähr übernehmen. Für die Inhalte der verlinkten Seiten ist stets der jeweilige Anbieter oder Betreiber der Seiten verantwortlich. Die verlinkten Seiten wurden zum Zeitpunkt der Verlinkung auf mögliche Rechtsverstöße überprüft. Rechtswidrige Inhalte waren zum Zeitpunkt der Verlinkung nicht erkennbar.

Eine permanente inhaltliche Kontrolle der verlinkten Seiten ist jedoch ohne konkrete Anhaltspunkte einer Rechtsverletzung nicht zumutbar. Bei Bekanntwerden von Rechtsverletzungen werden wir derartige Links umgehend entfernen.

Urheberrecht

Die durch die Seitenbetreiber erstellten Inhalte und Werke auf diesen Seiten unterliegen dem deutschen Urheberrecht. Die Vervielfältigung, Bearbeitung, Verbreitung und jede Art der Verwertung außerhalb der Grenzen des Urheberrechtes bedürfen der schriftlichen Zustimmung des jeweiligen Autors bzw. Erstellers. Downloads und Kopien dieser Seite sind nur für den privaten, nicht kommerziellen Gebrauch gestattet.

Soweit die Inhalte auf dieser Seite nicht vom Betreiber erstellt wurden, werden die Urheberrechte Dritter beachtet. Insbesondere werden Inhalte Dritter als solche gekennzeichnet. Sollten Sie trotzdem auf eine Urheberrechtsverletzung aufmerksam werden, bitten wir um einen entsprechenden Hinweis. Bei Bekanntwerden von Rechtsverletzungen werden wir derartige Inhalte umgehend entfernen.

Datenschutzerklärung

1. Datenschutz auf einen Blick

Allgemeine Hinweise

Die folgenden Hinweise geben einen einfachen Überblick darüber, was mit Ihren personenbezogenen Daten passiert, wenn Sie diese Website besuchen. Personenbezogene Daten sind alle Daten, mit denen Sie persönlich identifiziert werden können. Ausführliche Informationen zum Thema Datenschutz entnehmen Sie unserer unter diesem Text aufgeführten Datenschutzerklärung.

Datenerfassung auf dieser Website

Wer ist verantwortlich für die Datenerfassung auf dieser Website?

Die Datenverarbeitung auf dieser Website erfolgt durch den Websitebetreiber. Dessen Kontaktdaten können Sie dem Abschnitt „Hinweis zur Verantwortlichen Stelle“ in dieser Datenschutzerklärung entnehmen.

Wie erfassen wir Ihre Daten?

Ihre Daten werden zum einen dadurch erhoben, dass Sie uns diese mitteilen. Hierbei kann es sich z. B. um Daten handeln, die Sie in ein Kontaktformular eingeben.

Andere Daten werden automatisch oder nach Ihrer Einwilligung beim Besuch der Website durch unsere IT-Systeme erfasst. Das sind vor allem technische Daten (z. B. Internetbrowser, Betriebssystem oder Uhrzeit des Seitenaufrufs). Die Erfassung dieser Daten erfolgt automatisch, sobald Sie diese Website betreten.

Wofür nutzen wir Ihre Daten?

Ein Teil der Daten wird erhoben, um eine fehlerfreie Bereitstellung der Website zu gewährleisten. Andere Daten können zur Analyse Ihres Nutzerverhaltens verwendet werden.

Welche Rechte haben Sie bezüglich Ihrer Daten?

Sie haben jederzeit das Recht, unentgeltlich Auskunft über Herkunft, Empfänger und Zweck Ihrer gespeicherten personenbezogenen Daten zu erhalten. Sie haben außerdem ein Recht, die Berichtigung oder Löschung dieser Daten zu verlangen. Wenn Sie eine Einwilligung zur Datenverarbeitung erteilt haben, können Sie diese Einwilligung jederzeit für die Zukunft widerrufen. Außerdem haben Sie das Recht, unter bestimmten Umständen die Einschränkung der Verarbeitung Ihrer personenbezogenen Daten zu verlangen. Des Weiteren steht Ihnen ein Beschwerderecht bei der zuständigen Aufsichtsbehörde zu.

Hierzu sowie zu weiteren Fragen zum Thema Datenschutz können Sie sich jederzeit an uns wenden.

Analyse-Tools und Tools von Drittanbietern

Beim Besuch dieser Website kann Ihr Surf-Verhalten statistisch ausgewertet werden. Das geschieht vor allem mit sogenannten Analyseprogrammen.

Detaillierte Informationen zu diesen Analyseprogrammen finden Sie in der folgenden Datenschutzerklärung.

2. Hosting

Externes Hosting

Diese Website wird bei einem externen Dienstleister gehostet (Hoster). Die personenbezogenen Daten, die auf dieser Website erfasst werden, werden auf den Servern des Hosters gespeichert. Hierbei kann es sich v. a. um IP-Adressen, Kontaktanfragen, Meta- und Kommunikationsdaten, Vertragsdaten, Kontaktdaten, Namen, Websitezugriffe und sonstige Daten, die über eine Website generiert werden, handeln.

Der Einsatz des Hosters erfolgt zum Zwecke der Vertragserfüllung gegenüber unseren potenziellen und bestehenden Kunden (Art. 6 Abs. 1 lit. b DSGVO) und im Interesse einer sicheren, schnellen und effizienten Bereitstellung unseres Online-Angebots durch einen professionellen Anbieter (Art. 6 Abs. 1 lit. f DSGVO). Sofern eine entsprechende Einwilligung abgefragt wurde, erfolgt die Verarbeitung ausschließlich auf Grundlage von Art. 6 Abs. 1 lit. a DSGVO und § 25 Abs. 1 TTDSG, soweit die Einwilligung die Speicherung von Cookies oder den Zugriff auf Informationen im Endgerät des Nutzers (z. B. Device-Fingerprinting) im Sinne des TTDSG umfasst. Die Einwilligung ist jederzeit widerrufbar.

Unser Hoster wird Ihre Daten nur insoweit verarbeiten, wie dies zur Erfüllung seiner Leistungspflichten erforderlich ist und unsere Weisungen in Bezug auf diese Daten befolgen.

Wir setzen folgenden Hoster ein:

[Name und vollständige Anschrift des Hosters]

3. Allgemeine Hinweise und Pflichtinformationen

Datenschutz

Die Betreiber dieser Seiten nehmen den Schutz Ihrer persönlichen Daten sehr ernst. Wir behandeln Ihre personenbezogenen Daten vertraulich und entsprechend den gesetzlichen Datenschutzvorschriften sowie dieser Datenschutzerklärung.

Wenn Sie diese Website benutzen, werden verschiedene personenbezogene Daten erhoben. Personenbezogene Daten sind Daten, mit denen Sie persönlich identifiziert werden können. Die vorliegende Datenschutzerklärung erläutert, welche Daten wir erheben und wofür wir sie nutzen. Sie erläutert auch, wie und zu welchem Zweck das geschieht.

Wir weisen darauf hin, dass die Datenübertragung im Internet (z. B. bei der Kommunikation per E-Mail) Sicherheitslücken aufweisen kann. Ein lückenloser Schutz der Daten vor dem Zugriff durch Dritte ist nicht möglich.

Hinweis zur verantwortlichen Stelle

Die verantwortliche Stelle für die Datenverarbeitung auf dieser Website ist:

rbi GmbH

Im Rohrbach 18

57334 Bad Laasphe

Vertreten durch:

Gina Alisa Barth

Telefon: 02754 2208030

E-Mail: info@rbigmbh.de

Verantwortliche Stelle ist die natürliche oder juristische Person, die allein oder gemeinsam mit anderen über die Zwecke und Mittel der Verarbeitung von personenbezogenen Daten (z. B. Namen, E-Mail-Adressen o. Ä.) entscheidet.

Speicherdauer

Soweit innerhalb dieser Datenschutzerklärung keine speziellere Speicherdauer genannt wurde, verbleiben Ihre personenbezogenen Daten bei uns, bis der Zweck für die Datenverarbeitung entfällt. Wenn Sie ein berechtigtes Löschersuchen geltend machen oder eine Einwilligung zur Datenverarbeitung widerrufen, werden Ihre Daten gelöscht, sofern wir keine anderen rechtlich zulässigen Gründe für die Speicherung Ihrer personenbezogenen Daten haben (z. B. steuer- oder handelsrechtliche Aufbewahrungsfristen); im letztgenannten Fall erfolgt die Löschung nach Fortfall dieser Gründe.

Allgemeine Hinweise zu den Rechtsgrundlagen der Datenverarbeitung auf dieser Website

Sofern Sie in die Datenverarbeitung eingewilligt haben, verarbeiten wir Ihre personenbezogenen Daten auf Grundlage von Art. 6 Abs. 1 lit. a DSGVO bzw. Art. 9 Abs. 2 lit. a DSGVO, sofern besondere Datenkategorien nach Art. 9 Abs. 1 DSGVO verarbeitet werden. Im Falle einer ausdrücklichen Einwilligung in die Übertragung personenbezogener Daten in Drittstaaten erfolgt die Datenverarbeitung außerdem auf Grundlage von Art. 49 Abs. 1 lit. a DSGVO. Sofern Sie in die Speicherung von Cookies oder in den Zugriff auf Informationen in Ihr Endgerät (z. B. via Device-Fingerprinting) eingewilligt haben, erfolgt die Datenverarbeitung zusätzlich auf Grundlage von § 25 Abs. 1 TTDSG. Die Einwilligung ist jederzeit widerrufbar. Sind Ihre Daten zur Vertragserfüllung oder zur Durchführung vorvertraglicher Maßnahmen erforderlich, verarbeiten wir Ihre Daten auf Grundlage des Art. 6 Abs. 1 lit. b DSGVO. Des Weiteren verarbeiten wir Ihre Daten, sofern diese zur Erfüllung einer rechtlichen Verpflichtung erforderlich sind auf Grundlage von Art. 6 Abs. 1 lit. c DSGVO. Die Datenverarbeitung kann ferner auf Grundlage unseres berechtigten Interesses nach Art. 6 Abs. 1 lit. f DSGVO erfolgen. Über die jeweils im Einzelfall einschlägigen Rechtsgrundlagen wird in den folgenden Absätzen dieser Datenschutzerklärung informiert.

Widerruf Ihrer Einwilligung zur Datenverarbeitung

Viele Datenverarbeitungsvorgänge sind nur mit Ihrer ausdrücklichen Einwilligung möglich. Sie können eine bereits erteilte Einwilligung jederzeit widerrufen. Die Rechtmäßigkeit der bis zum Widerruf erfolgten Datenverarbeitung bleibt vom Widerruf unberührt.

Widerspruchsrecht gegen die Datenerhebung in besonderen Fällen sowie gegen Direktwerbung (Art. 21 DSGVO)

WENN DIE DATENVERARBEITUNG AUF GRUNDLAGE VON ART. 6 ABS. 1 LIT. E ODER F DSGVO ERFOLGT, HABEN SIE JEDERZEIT DAS RECHT, AUS GRÜNDEN, DIE SICH AUS IHRER BESONDEREN SITUATION ERGEBEN, GEGEN DIE VERARBEITUNG IHRER PERSONENBEZOGENEN DATEN WIDERSPRUCH EINZULEGEN; DIES GILT AUCH FÜR EIN AUF DIESE BESTIMMUNGEN GESTÜTZTES PROFILING. DIE JEWEILIGE RECHTSGRUNDLAGE, AUF DENEN EINE VERARBEITUNG BERUHT, ENTNEHMEN SIE DIESER DATENSCHUTZERKLÄRUNG. WENN SIE WIDERSPRUCH EINLEGEN, WERDEN WIR IHRE BETROFFENEN PERSONENBEZOGENEN DATEN NICHT MEHR VERARBEITEN, ES SEI DENN, WIR KÖNNEN ZWINGENDE SCHUTZWÜRDIGE GRÜNDE FÜR DIE VERARBEITUNG NACHWEISEN, DIE IHRE INTERESSEN, RECHTE UND FREIHEITEN ÜBERWIEGEN ODER DIE VERARBEITUNG DIENT DER GELTENDMACHUNG, AUSÜBUNG ODER VERTEIDIGUNG VON RECHTSANSPRÜCHEN (WIDERSPRUCH NACH ART. 21 ABS. 1 DSGVO).

WERDEN IHRE PERSONENBEZOGENEN DATEN VERARBEITET, UM DIREKTWERBUNG ZU BETREIBEN, SO HABEN SIE DAS RECHT, JEDERZEIT WIDERSPRUCH GEGEN DIE VERARBEITUNG SIE BETREFFENDER PERSONENBEZOGENER DATEN ZUM ZWECKE DERARTIGER WERBUNG EINZULEGEN; DIES GILT AUCH FÜR DAS PROFILING, SOWEIT ES MIT SOLCHER DIREKTWERBUNG IN VERBINDUNG STEHT. WENN SIE WIDERSPRECHEN, WERDEN IHRE PERSONENBEZOGENEN DATEN ANSCHLIESSEND NICHT MEHR ZUM ZWECKE DER DIREKTWERBUNG VERWENDET (WIDERSPRUCH NACH ART. 21 ABS. 2 DSGVO).

Beschwerderecht bei der zuständigen Aufsichtsbehörde

Im Falle von Verstößen gegen die DSGVO steht den Betroffenen ein Beschwerderecht bei einer Aufsichtsbehörde, insbesondere in dem Mitgliedstaat ihres gewöhnlichen Aufenthalts, ihres Arbeitsplatzes oder des Orts des mutmaßlichen Verstoßes zu. Das Beschwerderecht besteht unbeschadet anderweitiger verwaltungsrechtlicher oder gerichtlicher Rechtsbehelfe.

Recht auf Datenübertragbarkeit

Sie haben das Recht, Daten, die wir auf Grundlage Ihrer Einwilligung oder in Erfüllung eines Vertrags automatisiert verarbeiten, an sich oder an einen Dritten in einem gängigen, maschinenlesbaren Format aushändigen zu lassen. Sofern Sie die direkte Übertragung der Daten an einen anderen Verantwortlichen verlangen, erfolgt dies nur, soweit es technisch machbar ist.

Auskunft, Löschung und Berichtigung

Sie haben im Rahmen der geltenden gesetzlichen Bestimmungen jederzeit das Recht auf unentgeltliche Auskunft über Ihre gespeicherten personenbezogenen Daten, deren Herkunft und Empfänger und den Zweck der Datenverarbeitung und ggf. ein Recht auf Berichtigung oder Löschung dieser Daten. Hierzu sowie zu weiteren Fragen zum Thema personenbezogene Daten können Sie sich jederzeit an uns wenden.

Recht auf Einschränkung der Verarbeitung

Sie haben das Recht, die Einschränkung der Verarbeitung Ihrer personenbezogenen Daten zu verlangen. Hierzu können Sie sich jederzeit an uns wenden. Das Recht auf Einschränkung der Verarbeitung besteht in folgenden Fällen:

- Wenn Sie die Richtigkeit Ihrer bei uns gespeicherten personenbezogenen Daten bestreiten, benötigen wir in der Regel Zeit, um dies zu überprüfen. Für die Dauer der Prüfung haben Sie das Recht, die Einschränkung der Verarbeitung Ihrer personenbezogenen Daten zu verlangen.

- Wenn die Verarbeitung Ihrer personenbezogenen Daten unrechtmäßig geschah/geschieht, können Sie statt der Löschung die Einschränkung der Datenverarbeitung verlangen.

- Wenn wir Ihre personenbezogenen Daten nicht mehr benötigen, Sie sie jedoch zur Ausübung, Verteidigung oder Geltendmachung von Rechtsansprüchen benötigen, haben Sie das Recht, statt der Löschung die Einschränkung der Verarbeitung Ihrer personenbezogenen Daten zu verlangen.

- Wenn Sie einen Widerspruch nach Art. 21 Abs. 1 DSGVO eingelegt haben, muss eine Abwägung zwischen Ihren und unseren Interessen vorgenommen werden. Solange noch nicht feststeht, wessen Interessen überwiegen, haben Sie das Recht, die Einschränkung der Verarbeitung Ihrer personenbezogenen Daten zu verlangen.

Wenn Sie die Verarbeitung Ihrer personenbezogenen Daten eingeschränkt haben, dürfen diese Daten – von ihrer Speicherung abgesehen – nur mit Ihrer Einwilligung oder zur Geltendmachung, Ausübung oder Verteidigung von Rechtsansprüchen oder zum Schutz der Rechte einer anderen natürlichen oder juristischen Person oder aus Gründen eines wichtigen öffentlichen Interesses der Europäischen Union oder eines Mitgliedstaats verarbeitet werden.

SSL- bzw. TLS-Verschlüsselung

Diese Seite nutzt aus Sicherheitsgründen und zum Schutz der Übertragung vertraulicher Inhalte, wie zum Beispiel Bestellungen oder Anfragen, die Sie an uns als Seitenbetreiber senden, eine SSL- bzw. TLS-Verschlüsselung. Eine verschlüsselte Verbindung erkennen Sie daran, dass die Adresszeile des Browsers von „http://“ auf „https://“ wechselt und an dem Schloss-Symbol in Ihrer Browserzeile.

Wenn die SSL- bzw. TLS-Verschlüsselung aktiviert ist, können die Daten, die Sie an uns übermitteln, nicht von Dritten mitgelesen werden.

4. Datenerfassung auf dieser Website

Server-Log-Dateien

Der Provider der Seiten erhebt und speichert automatisch Informationen in so genannten Server-Log-Dateien, die Ihr Browser automatisch an uns übermittelt. Dies sind:

- Browsertyp und Browserversion

- verwendetes Betriebssystem

- Referrer URL

- Hostname des zugreifenden Rechners

- Uhrzeit der Serveranfrage

- IP-Adresse

Eine Zusammenführung dieser Daten mit anderen Datenquellen wird nicht vorgenommen.

Die Erfassung dieser Daten erfolgt auf Grundlage von Art. 6 Abs. 1 lit. f DSGVO. Der Websitebetreiber hat ein berechtigtes Interesse an der technisch fehlerfreien Darstellung und der Optimierung seiner Website – hierzu müssen die Server-Log-Files erfasst werden.

Kontaktformular

Wenn Sie uns per Kontaktformular Anfragen zukommen lassen, werden Ihre Angaben aus dem Anfrageformular inklusive der von Ihnen dort angegebenen Kontaktdaten zwecks Bearbeitung der Anfrage und für den Fall von Anschlussfragen bei uns gespeichert. Diese Daten geben wir nicht ohne Ihre Einwilligung weiter.

Die Verarbeitung dieser Daten erfolgt auf Grundlage von Art. 6 Abs. 1 lit. b DSGVO, sofern Ihre Anfrage mit der Erfüllung eines Vertrags zusammenhängt oder zur Durchführung vorvertraglicher Maßnahmen erforderlich ist. In allen übrigen Fällen beruht die Verarbeitung auf unserem berechtigten Interesse an der effektiven Bearbeitung der an uns gerichteten Anfragen (Art. 6 Abs. 1 lit. f DSGVO) oder auf Ihrer Einwilligung (Art. 6 Abs. 1 lit. a DSGVO) sofern diese abgefragt wurde; die Einwilligung ist jederzeit widerrufbar.

Die von Ihnen im Kontaktformular eingegebenen Daten verbleiben bei uns, bis Sie uns zur Löschung auffordern, Ihre Einwilligung zur Speicherung widerrufen oder der Zweck für die Datenspeicherung entfällt (z. B. nach abgeschlossener Bearbeitung Ihrer Anfrage). Zwingende gesetzliche Bestimmungen – insbesondere Aufbewahrungsfristen – bleiben unberührt.

Anfrage per E-Mail, Telefon oder Telefax

Wenn Sie uns per E-Mail, Telefon oder Telefax kontaktieren, wird Ihre Anfrage inklusive aller daraus hervorgehenden personenbezogenen Daten (Name, Anfrage) zum Zwecke der Bearbeitung Ihres Anliegens bei uns gespeichert und verarbeitet. Diese Daten geben wir nicht ohne Ihre Einwilligung weiter.

Die Verarbeitung dieser Daten erfolgt auf Grundlage von Art. 6 Abs. 1 lit. b DSGVO, sofern Ihre Anfrage mit der Erfüllung eines Vertrags zusammenhängt oder zur Durchführung vorvertraglicher Maßnahmen erforderlich ist. In allen übrigen Fällen beruht die Verarbeitung auf unserem berechtigten Interesse an der effektiven Bearbeitung der an uns gerichteten Anfragen (Art. 6 Abs. 1 lit. f DSGVO) oder auf Ihrer Einwilligung (Art. 6 Abs. 1 lit. a DSGVO) sofern diese abgefragt wurde; die Einwilligung ist jederzeit widerrufbar.

Die von Ihnen an uns per Kontaktanfragen übersandten Daten verbleiben bei uns, bis Sie uns zur Löschung auffordern, Ihre Einwilligung zur Speicherung widerrufen oder der Zweck für die Datenspeicherung entfällt (z. B. nach abgeschlossener Bearbeitung Ihres Anliegens). Zwingende gesetzliche Bestimmungen – insbesondere gesetzliche Aufbewahrungsfristen – bleiben unberührt.